Information about MoCl5, NbCl5, TaCl5 & WCl6 compounds

MoCl5 — Molybdenum(V) Chloride A dark red crystalline solid used as a precursor in molybdenum chemistry. It forms dimers and reacts readily with moisture, producing HCl and molybdenum oxides.

Commonly used in organic synthesis and materials preparation.

NbCl5 — Niobium(V) chloride. A pale yellow, air-sensitive solid that exists as dimers in the solid state.

It acts as a Lewis acid and is used in organic synthesis and metal complex formation.

NbCl5 hydrolyzes easily, requiring handling under dry conditions.

TaCl5 — Tantalum(V) chloride. A white to yellow solid structurally similar to NbCl₅, forming dimers (Ta5Cl10). It is used in the synthesis of tantalum compounds and as a CVD precursor.

Highly reactive with water, it must be stored in inert conditions.

WCl6 — Tungsten(VI) chloride. A dark blue-violet solid with tungsten in the +6 oxidation state.

It is volatile, moisture-sensitive, and used in high-purity tungsten chemistry.

WCl₆ is valuable in research, catalysis, and advanced material synthesis.

Molybdenum(V) Chloride

Molecular Formula: MoCl₅

Molecular Weight: 273.2g/mol

Purity: 99.9%

CAS No.: 10241-05-1

UN No.: 2508

Transport hazard class: 8

Chemical Properties

Decomposes in humid air or water. Soluble in concentrated hydrochloric acid and sulfuric acid,

forming corresponding compounds.

Catalysis

MoCl₅ is used as a catalyst for the polymerization of various monomers, including

ethylene, butadiene, and trioxane.

Physical Properties

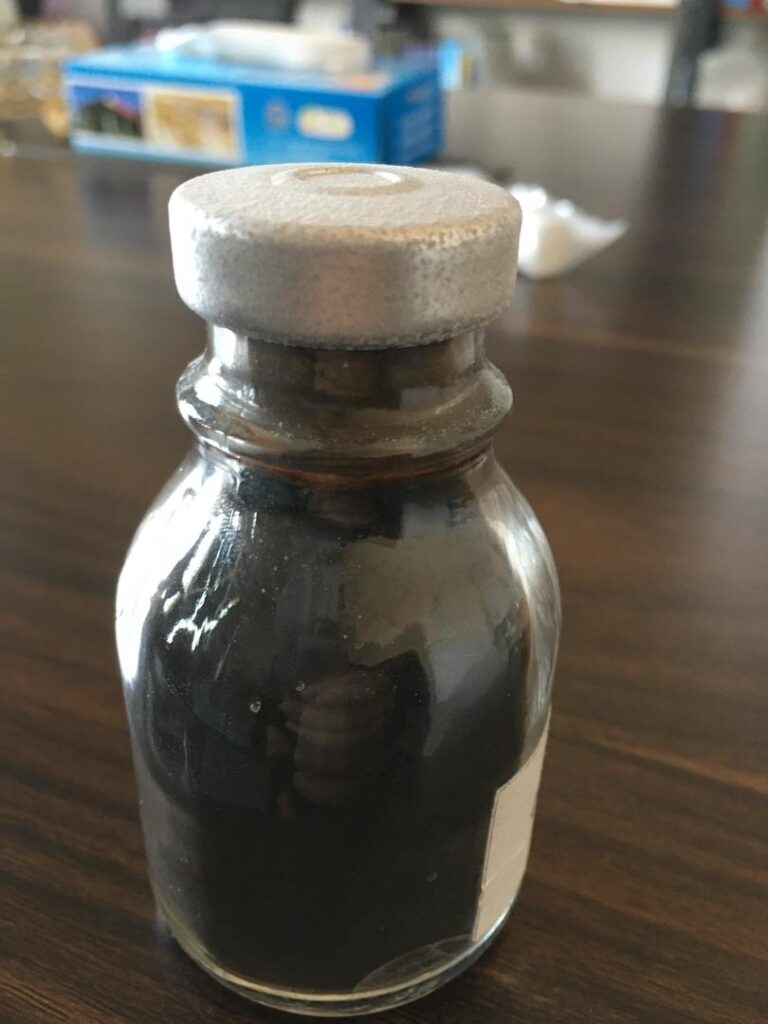

Dark green or gray-black crystals; solution or vapor appears dark red

Soluble in various anhydrous alcohols and ethers

| Melting Point | 194°C |

| Boiling Point | 268°C |

| Density | 2.93 g/cm³ |

Packaging and Specifications

Available in glass or metal containers.

Standard sizes: 100g, 500g, 1kg.

Custom packaging available upon request.

Other Applications

• Chemical Vapor Deposition (CVD):

MoCl₅ is used in thin films and coatings for the electronics industry. It serves as a precursor in CVD and ALD processes, especially in the manufacturing of microprocessors and memory chips.

• Synthesis of Molybdenum Compounds:

MoCl₅ is used in the production of molybdenum disulfide (MoS₂) and molybdenum carbide

Storage Conditions

Store in a cool, dry, and well-ventilated warehouse. Keep away from fire and heat sources. Packaging must be completely sealed to prevent moisture absorption. Store separately from oxidizing agents; avoid mixed storage. Suitable materials should be available in the storage area to contain any potential leaks.

Niobium Pentachloride or Niobium (V) chloride

Molecular Formula: NbCl₅

Molecular Weight: 270.17g/mol

Purity: 99.9% or 99.99%

CAS No.: 10026-12-7

UN No.: 3260

Transport hazard class: 8,Packing Group II

Note: Various concentrations of niobium pentachloride (NbCl5) in alcohol

solutions are available.

Chemical Properties

Solubility: Soluble in alcohol, hydrochloric acid, chloroform, and carbon tetrachloride.

Reactivity: Highly reactive, hydrolyzes in humid conditions to form NbOCl3 and HCl, necessitating

dry handling and storage.

Physical Properties

Yellow crystalline solid.

| Melting Point | 204.7°C |

| Boiling Point | 254°C |

| Density | 2.75 g/cm³ |

Packaging and Specifications

Available in glass or metal containers.

Standard sizes: 100g, 500g, 1kg.

Custom packaging available upon request.

Catalysis

NbCl₅ serves as a Lewis acid catalyst in organic synthesis to activate olefins

Industrial Uses

The NbCl5 is the production of pure niobium metal via the Hunter process, where it is reduced with magnesium or sodium

Chemical Vapor Deposition (CVD)

NbCl₅ is used in thin films and coatings for the electronics industry. It serves as a precursor in CVD and ALD processes, especially in the manufacturing of microprocessors and memory chips.

Storage Conditions

Store in a cool, dry, and well-ventilated warehouse. Keep away from fire and heat sources. The storage temperature must be lower than 37°C. Packaging must be completely sealed to prevent moisture absorption. Store separately from oxidizing agents; avoid mixed storage.

Tantalum Pentachloride or Tantalum(V) chloride

Molecular Formula: TaCl₅

Molecular Weight: 358.21g/mol

Purity: 99.9% or 99.99%

CAS No.: 7721-01-9

UN No.: 3260

Transport hazard class: 8,Packing Group II

Note: Various concentrations of niobium pentachloride (NbCl5) in alcohol

solutions are available.

Chemical Properties

Solubility: Soluble in aromatic hydrocarbons such as benzene, toluene, and xylene;

insoluble in cyclohexane and carbon tetrachloride.

Reactivity: Highly reactive; hydrolyzes in moist air to form tantalum oxychloride (TaOCl3)

and hydrochloric acid (HCl), requiring anhydrous conditions for handling.

Physical Properties

White to light yellow crystalline solid.

| Melting Point | 221°C |

| Boiling Point | 242°C |

| Density | 3.68 g/cm³ |

Packaging and Specifications

Available in glass or metal containers.

Standard sizes: 100g, 500g, 1kg.

Custom packaging available upon request.

Catalysis

TaCl₅ serves as a Lewis acid catalyst in organic synthesis .

Industrial Uses

The TaCl5 is the production of pure tantalum metal , where it is reduced with magnesium or sodium

Chemical Vapor Deposition (CVD)

TaCl₅ is used in thin films and coatings for the electronics industry. It serves at CVD and ALD processes, especially in the manufacturing of microprocessors and memory chips.

Storage Conditions

Store at room temperature in a fluorinated bottle filled with an inert gas, and well-ventilated warehouse.

Tungsten Hexachloride (WCl₆)

Molecular Formula: WCl₆

Molecular Weight: 396.61g/mol

CAS No.: 13283-01-7

UN No.: 3260

Transport hazard class: 8

Note: Various concentrations of tungsten hexachloride (WCl₆) in alcohol

solutions are available.

Storage Conditions

Store in a sealed container at room temperature in a cool, dry, and

well-ventilated area.

Physical Properties

Dark gray or blue-purple solid.

| Melting Point | 275°C (decomposes) |

| Boiling Point | 347°C |

Packaging and Specifications

Sealed in PE containers. Available in 10 kg, 1 kg, and 2 kg bottles. Custom

packaging is available upon request.

Applications

Agricultural Industry

WCl₆ is mainly used in the synthesis of pesticide precursors, including:

1. Aromatic Compounds: Catalyzes Friedel-Crafts alkylation/acylation to produce pesticide intermediates.

2. Heterocyclic Compounds: Facilitates the synthesis/modification of pyridine, pyrimidine, thiazole, and similar structures.

3. Polymer Carriers: Catalyzes olefin polymerization for controlled-release pesticide carriers.

1. Insecticide Precursors

•Precursor Types: Aromatic and heterocyclic compounds

•Specific Substances:

-Chlorobenzene: Undergoes Friedel-Crafts reactions to form organophosphorus insecticide intermediates, such as dichlorvos.

-Pyridine: Catalyzes pyridine synthesis/modification, essential for neonicotinoid insecticides like imidacloprid.

2. Herbicide Precursors

•Precursor Types: Aromatic and pyrimidine-based compounds

•Specific Substances:

-Toluene: Undergoes alkylation reactions to form benzene-based herbicide intermediates.

-Pyrimidine: Catalyzes pyrimidine synthesis, a key structure in sulfonylurea herbicides like nicosulfuron.

3. Fungicide Precursors

•Precursor Types: Heterocyclic compounds

•Specific Substances:

-Thiazole: Catalyzes thiazole ring formation, found in fungicides such as thiabendazole.

-Phenol: Undergoes Friedel-Crafts modifications for fungicide intermediates.

4. Polymer Carriers (Pesticide Adjuvants)

•Precursor Types: Olefins

•Specific Substances:

-Ethylene: Catalyzes polymerization into polyethylene, used as a slow-release pesticide carrier.

-Propylene: Catalyzes polymerization into polypropylene, used in pesticide formulations.

Petrochemical Industry (Catalyst Applications)

- Hydrocracking: WCl₆ acts as a catalyst to break down heavy hydrocarbons into lighter fuels (e.g., gasoline, diesel) at lower temperatures and pressures, improving reaction efficiency and selectivity.

- Isomerization: Catalyzes hydrocarbon isomerization, converting straight-chain hydrocarbons into branched or cyclic structures to enhance fuel quality and octane rating.

- Dehydrogenation: Facilitates hydrocarbon dehydrogenation, producing unsaturated compounds like styrene, a key monomer in synthetic rubber and plastics.

- Desulfurization: Promotes sulfur removal from petroleum products to reduce environmental pollution and equipment corrosion, ensuring compliance with environmental standards.

Materials Science

- Chemical Vapor Deposition (CVD) of Tungsten Coatings: WCl₆ reacts with hydrogen at high temperatures to deposit uniform, dense tungsten coatings, improving hardness, wear resistance, and corrosion resistance in aerospace and mold applications.

- Single-Crystal Tungsten Wire Production: Used to manufacture single-crystal tungsten wire with excellent mechanical, electrical, and high-temperature stability properties, widely applied in electron tubes, incandescent lamps, and electron beam melting.

- Conductive Glass Coatings: Processed WCl₆ forms tungsten-based conductive films on glass surfaces, applicable in LCDs, touchscreens, and solar panels as transparent conductive electrodes.